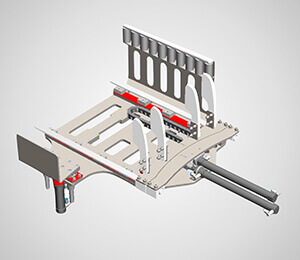

Mechanical engineering projects

From the need to the implementation

At EGON we offer innovative and fully customised technological solutions to our customers. Tailor-made projects to meet your needs and improve your production process. Below you can see a small sample of projects that we have carried out for different sectors.

EGON working philosophy

We approach all our projects with the same methodology, regardless of the volume or type of project. This work philosophy leads us to raise the standards of demand and quality in pursuit of excellence.

- Meeting / briefing with initial specification taking at the client's premises.

- We develop and design the work cycles of the machines, simulating the integration into the customer's production process.

- We carry out the detailed design of the entire project.

- DIn parallel and on an on-going basis, we discuss and review the complete design with our clients, explicitly validating the initial specifications.

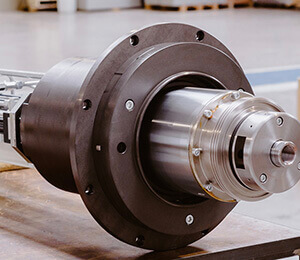

- We manufacture the machines and production lines in our own facilities, as we have our own precision machining workshop.

- We carry out the commissioning on our premises, as we have an assembly hall, in the presence of the customer.

- We undertake the production start-up at our clients' facilities, carrying out the final validation, training of personnel and delivery of the project documentation together with the corresponding CE marking.