Development of industrial prototypes

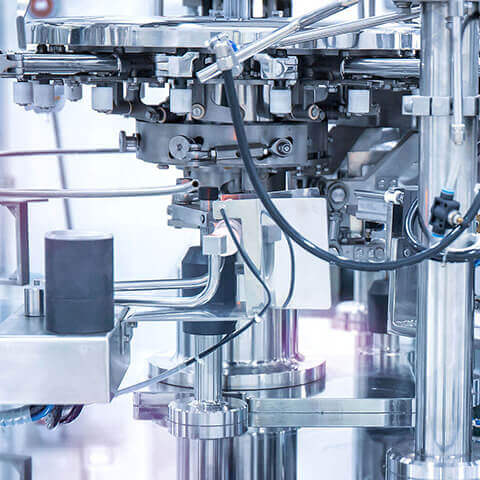

At EGON we manufacture and develop prototypes for different industrial solutions. We use 3D printing to preview and validate possible future designs at an early stage, before incurring unnecessary manufacturing costs.

EGON, in addition to having a workshop specialised in high precision machining with CNC machines for machined prototypes, has 3D printing machines for prototypes that allow to verify and validate the designs before deciding on the final production.

The manufacture and development of prototypes allows our design and engineering team to optimise the parts from a functional point of view, their mechanical resistance and the amount of material used for their manufacture, with a direct impact on the reduction of the client's manufacturing costs.

We can develop prototypes in both ABS and Polyamide up to a size of 500 x 500 x 200mm, with different densities, surface qualities and resistances.

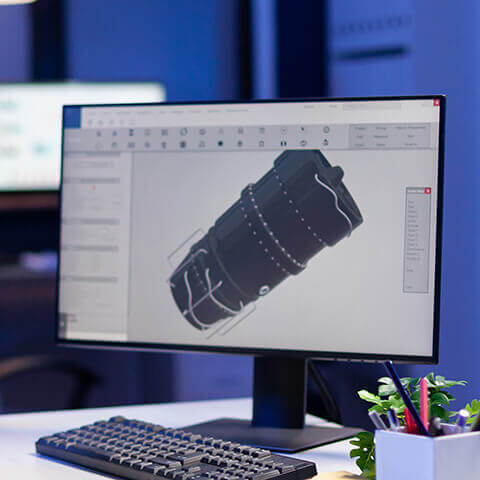

Nowadays it is very common to develop rapid prototyping of parts in industrial processes, with the aim of generating an exact three-dimensional replica of complex parts by means of 3D CAD application.

Fast prototyping is key to improving project management times, allowing the validation of parts from the dimensional, functional and aesthetic points of view, before launching the manufacture of real prototypes and final series production.

Fast prototyping is characterised by relatively short modelling times, allowing parts to be quickly available to undergo the necessary validations.